Turn Your Team From Reactive to Proactive.

Workforce will help:

- Improve Employee Engagement

- Increase Employee Productivity

- Reduce Labor Cost

- Save Time Collecting & Inputting Data

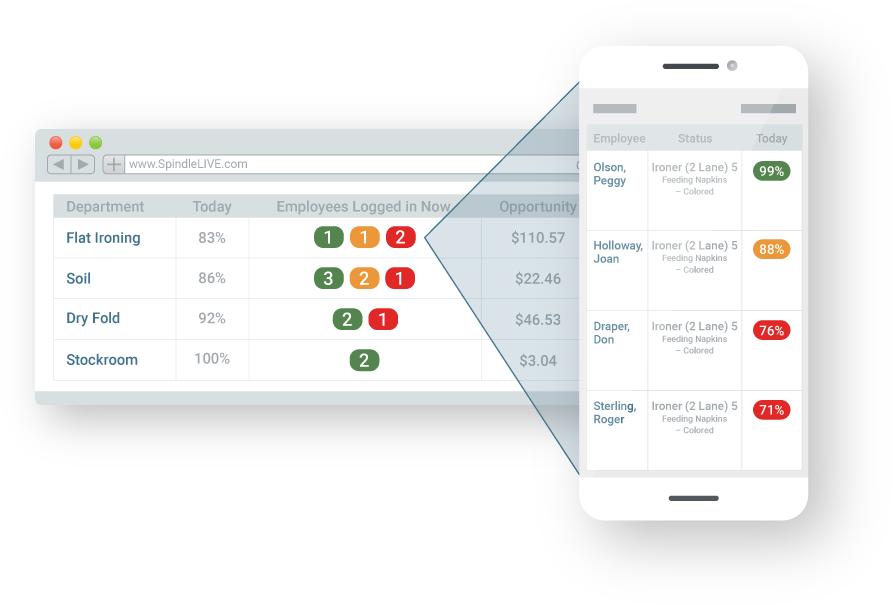

Focus on Your Biggest Opportunities Each Day

Supervisors know where there are opportunities to improve before even walking on the floor. The real-time information is actionable and easy to use.

Quickly sort by 'Opportunity' and visualize the department in your plant that's costing you the most money.

Visualize Employee Productivity

Employees can view where they stand against their performance goals and receive immediate feedback based on objective and real-time data

We’ve found that productivity increases by 5-10% by simply adding a visual workplace.

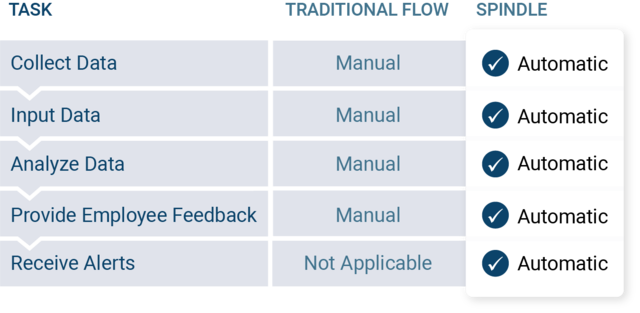

Save Time and Improve Data Integrity

Spindle automates the collection of data across your entire operation.

This not only saves you and your team time, but also reduces the exposure to human error. Ensuring the data you do receive and act on is accurate and objective.

Gain Access to Our Industry Leading Experts

We eat, sleep, and breathe lean manufacturing, which means our partnership doesn’t end once we install the equipment. After we on-board your staff, our industry experts will continue to coach your team on best practices and provide actionable insights into areas of your plant that are under performing.

Together, we'll have your plant running as efficiently as possible.

Additional Features

Monitor Non-Standard Tasks

We don't just measure standard tasks, but non-standard tasks too. In other words, we track everything around your plant.

Powerful Analytics

Break your operation's numbers down by department, classifications, employees, or equipment. You'll be able to uncover opportunity across your entire plant.

Continuous Improvement

We're constantly improving our product. With our in house development team, we release an update remotely every two weeks.

“With Spindle, we went from eighth in our region to No. 1. In fact, our WPOH (Weight per operator hour) is now consistently among the highest in the entire company. Our completion of loads and our throughput have improved greatly as well.”