Less Equipment Downtime. More Production Time.

Spindle's Equipment Utilization Will Help You:

- Improve Capacity Utilization

- Monitor Overall Equipment Effectiveness

- Make Better Capex Decisions

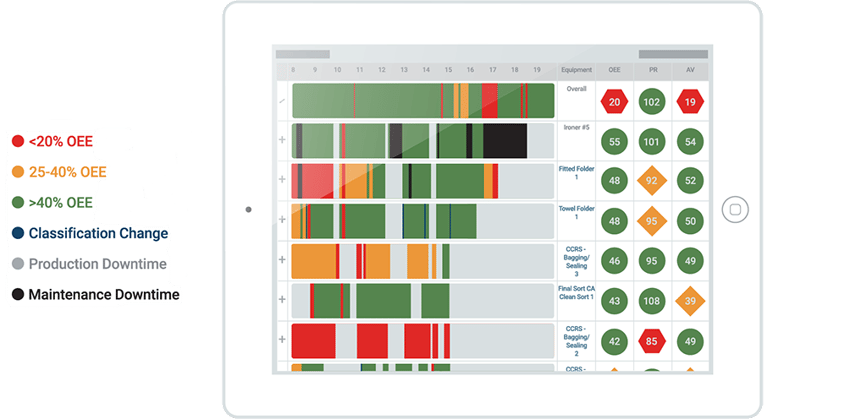

Real-time Insight into Bottlenecks

Quickly find areas in your plant that are slowing your operation. Are you changing classifications on a machine too often? Is the same equipment consistently going down for maintenance? Are your employees performing poorly or is it your equipment? How are you tracking your equipment downtime?

Equipment Utilization automates the collection of data that already exists in your plant and presents the information to you in easy to interpret dashboards. This higher visibility into your plant makes operating at peak performance the new norm.

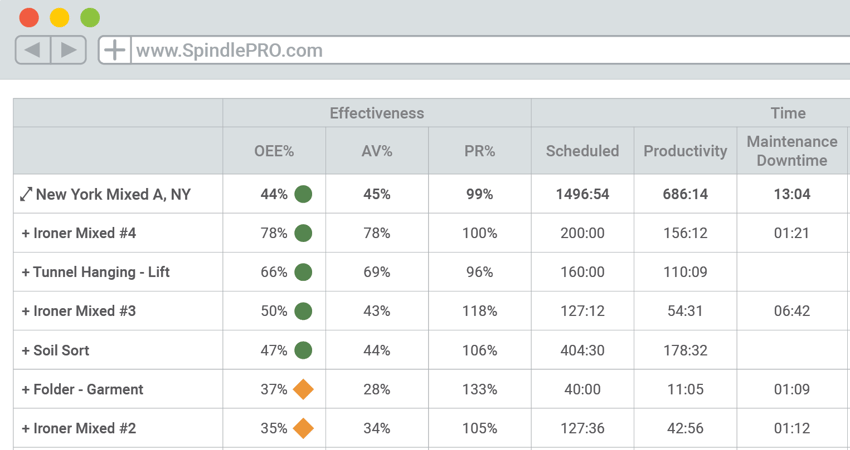

Prevent Costly CapEx Decisions

With an improved visibility into capacity constraints, Equipment utilization simplifies difficult questions like, "Do I need to buy new equipment to meet the additional demands of a new account?"

By displaying true representations of how equipment is being utilized, you can make more informed, data-backed decisions regarding your plant.

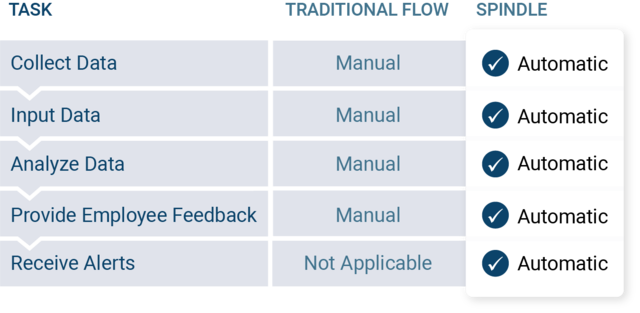

Save Time and Improve Data Integrity

Spindle automates the collection of data across your entire operation.

This not only saves you and your team time, but also reduces the exposure to human error. Ensuring the data you do receive and act on is accurate and objective.

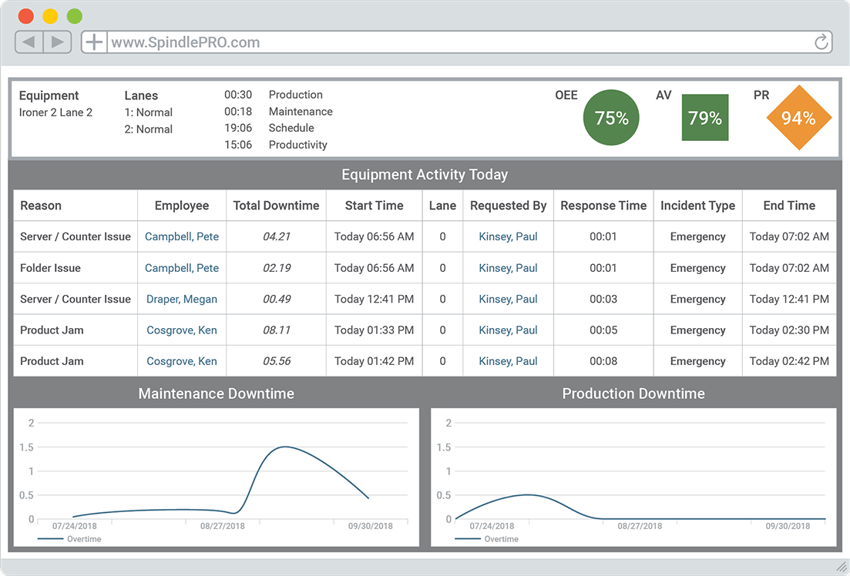

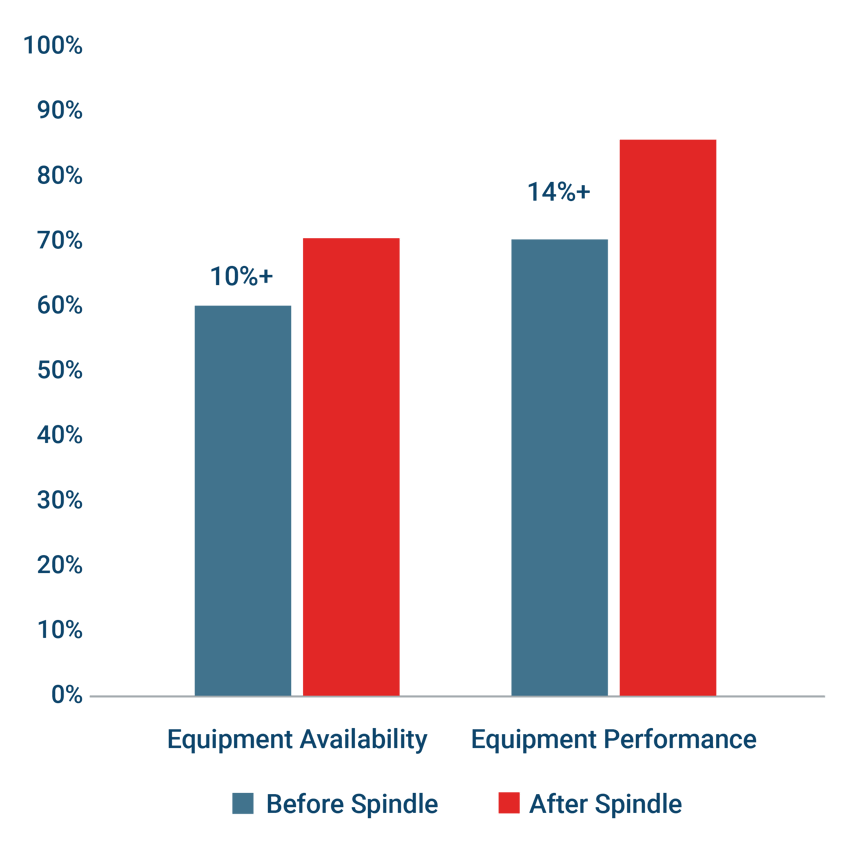

Boost Efficiency By Improving Equipment Availability

Monitor your plant down to the individual machine and uncover trends regarding the underlying reason for high frequency breakdowns in your equipment.

Equipment Utilization helps you create the optimal preventative maintenance schedule and eliminate these repetitive breakdowns -- ensuring more equipment uptime.

Improve Overall Equipment Effectiveness

Quickly visualize your plants Overall Equipment Effectiveness (OEE) to see where capacity is lost. SpindlePRO summarizes capacity losses with the capability to drill down to the equipment and lane level.

By streamlining your workflow and improving the efficiency around your plant, you're able to have a more predictable throughput and do more with less.

Includes all the amazing features of Spindle Workforce and more.

Maintenance Employee Status

Quickly view where your maintenance team members are logged into around your plant.

Maintenance Incidents by Employee

View historical data regarding equipment breakdowns to identify areas employees may need to be coached to prevent product jams.

Downtime Analysis

Real-time tracking analysis offers context and reporting for when production is low, such as when maintenance took place, or employees were unavailable.

Continuous Improvement

We're constantly improving our product. With our in house development team, we release an update remotely every two weeks.

"With Spindle we realized we did not need an additional Ironing Line to support our demand, because we were able to hold our team accountable to standards."