Maintenance Management Software to Limit Downtime & Extend the Longevity of Your Equipment

Our CMMS software helps you monitor all maintenance tasks for your maintenance team in real-time.

- Schedule & Track Preventive Maintenance

- Work Order Management

- Parts Inventory Management

- Real-Time Reporting

-1.png?width=800&height=750&name=benefits%20MAINTENANCE%20PROGRAM%20(2)-1.png)

Why is a Preventive Maintenance Program Important?

All machines eventually break down unless properly maintained. That's why the best-in-class manufacturing facilities have a robust preventive maintenance program.

Not only does a proper maintenance program limit unexpected down time, but it also extends the longevity of your equipment.

All Your Maintenance Tasks in One Place.

No need to track maintenance tasks in excel spreadsheets or on paper. All of your maintenance tasks now live in one place.

Easily create work orders, schedule, and assign tasks to your maintenance workers from anywhere.

.png?width=800&height=800&name=Engagement%20_Search%20For_%20Instagram%20%26%20Facebook%20Post%20(1).png)

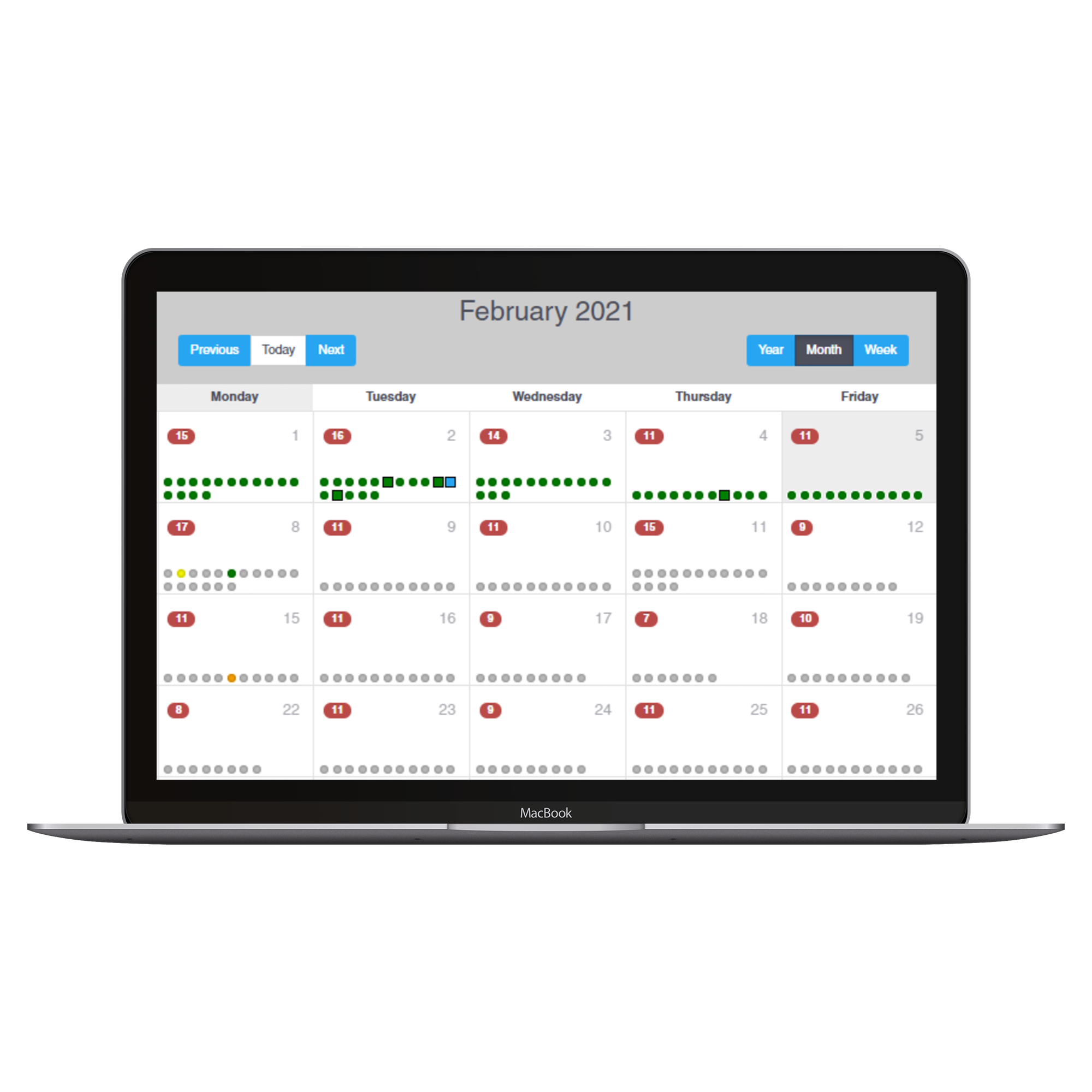

Visualize the Status of Each Task with the Maintenance Calendar

Visualize the status of how your maintenance team has performed in the past and what lies ahead in the coming weeks.

Jump to any work order directly from the calendar view.

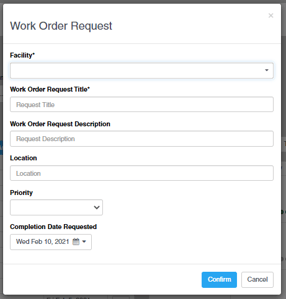

Create Work Order Requests in Minutes

Quickly identify and create potential repairs that can be approved by management level personnel.

Set priority levels, cost, labor hours, and schedule work orders after approval.

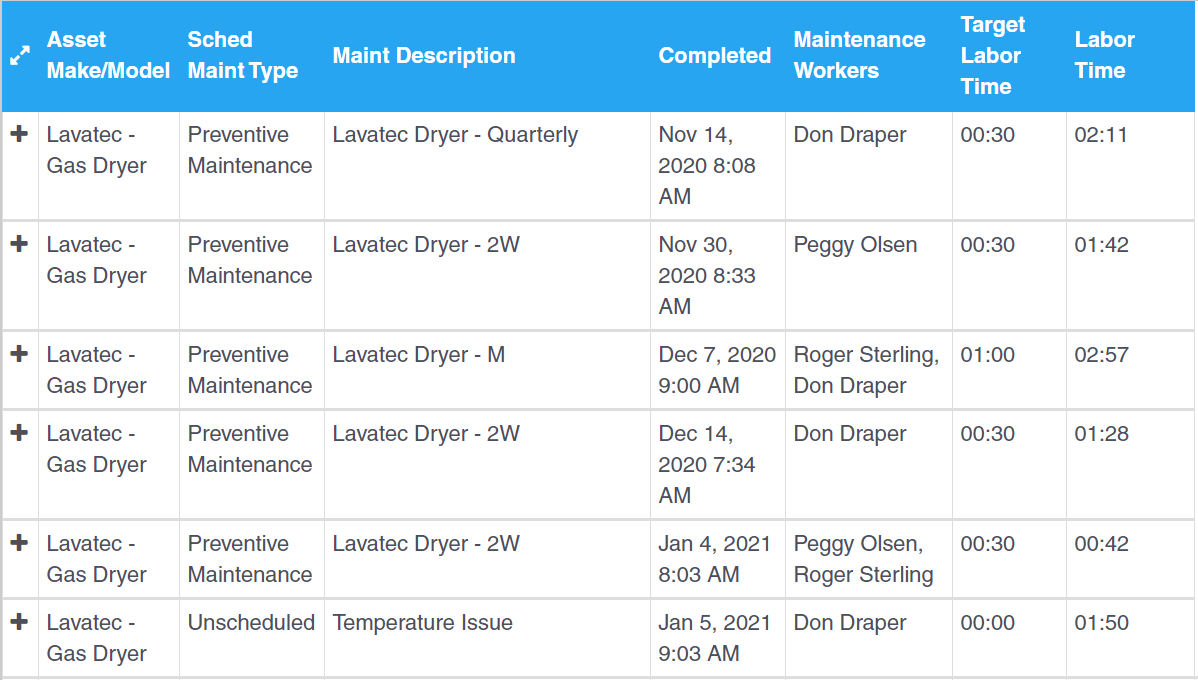

Track Actual Labor Time vs Scheduled Labor Time

You can't improve what you don't measure. By comparing the actual time vs expected time to complete tasks, your organization can identify work order effectiveness.

Review the Entire History of Maintenance on Any Asset

View maintenance history on any asset and drill down into each individual work order to get a complete understanding of your maintenance history.

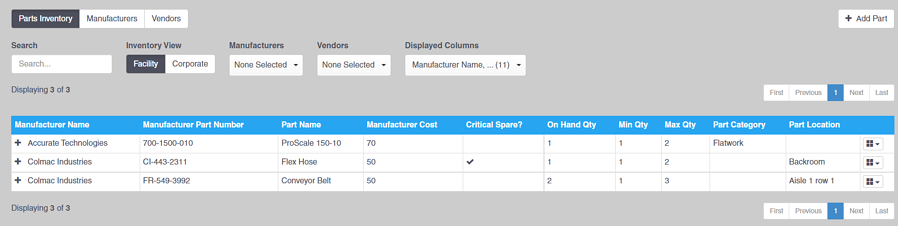

Parts Inventory Management

Quickly understand the status of critical spare parts inventory, identify preferred vendors to purchase from, and manage stock levels to ensure you are only purchasing what you need.

For companies that have multiple locations, identify parts you need that are stored at another location within your organization

More Powerful Maintenance Features

Programmable Preventive Maintenance Library

If you manage more than one location you can add, edit, and delete PM tasks that instantly get applied to all locations. Saving you time. Lots of time.

Run Customized Reports

Run customized reports on nearly anything you like - filter by equipment type, department, employee or status, just to name a few.

Maintenance Instructions

Add step by step instructions that require signoff to ensure a step is never forgotten - no matter how small.

Continuous Improvement

We're constantly improving our product. With our in house development team, we release an update remotely every two weeks.

"We installed Spindle for our CMMS and have had tremendous success"