AI-Powered Vision.

Smarter Laundry.

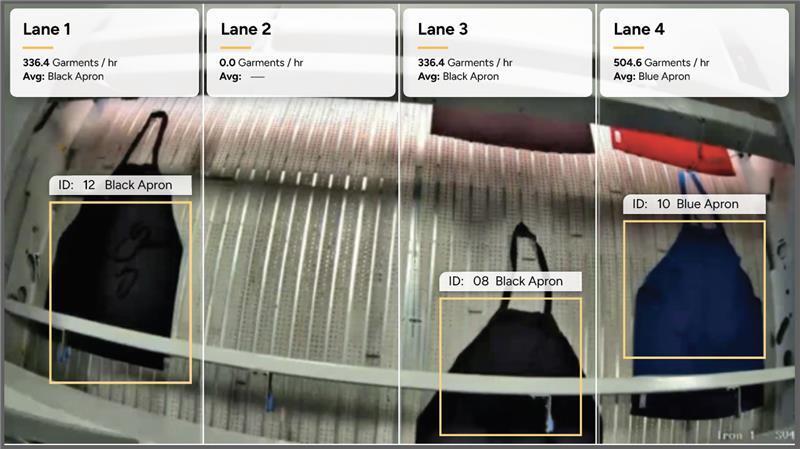

Eliminate blind spots in your operation by tapping into Spindle’s advanced computer vision for nonstop, real-time visibility.

Know What's Really Happening Inside Your Plant

Laundries are complex environments: fast-moving, labor-intensive, and filled with variables that are hard to quantify. Traditional tools can only go so far.

Spindle Vision brings AI-powered computer vision to your operation, revealing insights that were previously unmeasurable.

From workflow gaps to measuring tasks with no standards and missed quality checks, it helps you see what’s actually happening, not just what’s recorded.

Know Who’s Working, Without a Single Login

Spindle Vision uses advanced facial recognition to automatically understand who’s working, what they’re working on, and how efficiently they’re performing, down to the task, shift, and department. No more login stations. No more hardware installs.

Operators don’t have to touch a thing. You get real-time visibility into time-on-task, productivity, and behavior without disrupting flow.

That means accountability without friction, and it’s changing the game for your laundry.

What's Next?

Proactively detect risks, protect your team, and raise quality standards.

Laundries are naturally high-risk environments. They're hot, fast-moving, and filled with heavy machinery. Traditional safety systems often react too late or miss warning signs entirely.

That's why we have an entire backlog dedicated toward building safety and quality into the fabric of plant operations.

Virtual Boundaries

With safety in mind, create virtual boundaries for high-risk locations and monitor worker entry and exit. Automatically identify workers who are not properly equipped with safety gear.

Near-Miss Detection

Detect near-miss situations with moving equipment such as laundry carts, overhead slings, etc.

Hear from Our Customers

“The ongoing monitoring by Spindle and regular feedback with actionable information is what sets them apart.”

"Awesome system. Gives you the ability to coach staff to improve productivity. Great reporting functions gives you a wide array of data to improve your production."

"Could not function efficiently without the Spindle system."

Never Feel in the Dark Again

With so much happening on your plant floor, it’s easy to feel like you don’t know what’s happening in every corner of your operation. Vision takes that uncertainty away and replaces it with a crystal-clear perspective that addresses the “who, what, where, when, and why” of your operations.